Standard Brake Job Tips

I wanted to provide some standard brake job tips that can apply to both do it yourself driveway mechanics and auto repair consumers that plan on dropping their vehicle off for brake service. Learning a little about the process can help you get the most out of your brake jobs.

In some auto repair publications they have done tests showing that when only the pads are replaced without reconditioning or replacing the caliper hardware the new pads can wear out faster than original equipment brake pads installed from the factory.

It’s often rusting and corrosion that causes this premature wear. When the calipers don’t float as per design intent then the brakes can drag slightly causing this increased wear. I have more details about the different kinds of disc brakes and how they work plus an auto repair video at the very end of this article.

This is my primary brake job tips recommendation. When you’re performing your own brake service or you’re having a shop do it for you, replace or fully recondition the hardware that allows for the free movement of the calipers. Think about where this hardware is located. Down by the tire and close to the road where it’s exposed to water, salt, potholes and road debris.

In fact most manufacturers recommend that these pins and bushings be replaced each time the caliper is removed. This is a good idea, because the pins and bushings are usually inexpensive and will assure not only longer pad life, but also more efficient and even braking.

Getting Good Brake Job Tips

As a mechanic when it comes to performing a brake job whether it’s on my own vehicle or a customer’s car I always insist on taking a road test before work begins. This way I know what the brakes feel like before I take them apart.

This can also greatly reduce poor communication between the mechanic and the driver. Sometimes people will take their vehicle in for a brake job, drop the vehicle off and say replace my front brakes. The driver of the vehicle might believe a specific problem will be solved by that operation without notifying the shop of the issue.

Another big point to make, is I will not release the vehicle after performing brake service without driving it myself. Often mechanics and shops are so pressed for time they will install the pads and park the vehicle with the intention to drive it later. Then the day slips by and it’s released to the customer without any road test. This should never happen, but it does.

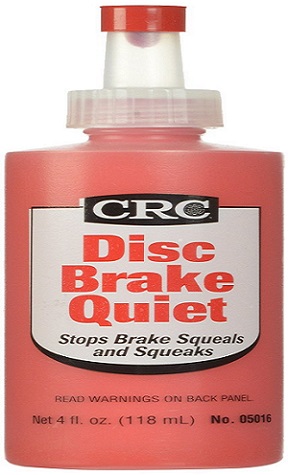

First of all new brake pads may need some brake in time before they will feel like the old brake pads did. I road test the vehicle and perform both panic stops and regular braking to make sure everything went as planned. It’s very important for the vehicle to stop the same way or better as when the driver dropped off the automobile for service. Drivers are often sensitive to brake noise so these issues should be addressed before releasing the automobile.

Types of Disk Brakes

The disc brakes in use today are typically of two basic designs. I believe the most common would be the floating caliper design. You can also find the fixed caliper design as well. There is also a sliding caliper but this is very similar to a floating caliper type disc brake system.

The difference between a sliding caliper and a floating one would be that the sliding type has a smooth machined surface that it moves up and back in. The floating calipers will slide on special pins, bolts and bushings. On this type there is a space called an air gap between the mounting bracket and the caliper. On full floating type brakes you will usually have pistons on only one side of the caliper.

Fixed caliper disc brakes have an assembly that is bolted in a fixed position and does not move when the brakes are applied. In this type of situation the caliper will have pistons on both sides that use hydraulic force multiplied from the driver’s foot to force the brake pads against the rotor. This friction is what stops the vehicle with authority.

Learning about what type of braking system is on your specific automobile and being able to discuss this from an educated position can increase the chances of getting a quality brake job. I have built a complete repair module on the youfixcars.com website that walks you through a few more important brake job tips. If you’re interested in seeing the latest post on this site this next link takes you back to the auto repair information blog.