The Direction of Plastic Automotive Technology

Glaring problems with the direction of plastic automotive technology become more apparent every day. Common failures across a wide variety of popular models dominate the list of YouTube videos in the automotive vertical. When we drill down and examine these individual car problems we often find the failure of plastic components.

On cars from the 1970s and 80s they made engines and cylinder heads out of cast-iron. With the tightening of corporate average fuel economy standards vehicle manufacturers found it necessary to lighten these vehicles to improve miles per gallon. By the 90s, we found most of these automobiles with aluminum intake manifolds, cylinder heads and engine blocks.

Aluminum is a strong, lightweight material. However, plastic is even lighter and less expensive. Notice I didn’t include the word strong in the description of plastic. In an effort to increase profit margins while increasing fuel economy, manufacturers have ramped up their efforts to install plastic parts in the engine compartment. Plastic Intake manifolds, thermostat housings, timing covers and emission sensors dominate under the hood of the latest automobiles.

The question is how long a plastic part will last when it’s mounted directly to an internal combustion engine. Internal combustion means high temperatures. Generally speaking, heat is not the friend of plastic. When you spend $50,000 on a new automobile you expect it to last at least 15 years without major service. The question is will it. Has the lightning of the automobile gone too far? And what about these light-duty plastic parts when combined with driverless car technology. Let’s start by discussing some of the parts no longer made from a metal alloy.

Plastic Automotive Trim Pieces

One of the things that classic car enthusiasts love about automobiles from the 50s and 60s is what they call bright work. Chrome trim pieces made from metal. These parts lasted for 50 years or more before they needed a re-chrome. Slowly we started replacing these beloved body accents with plastic trim.

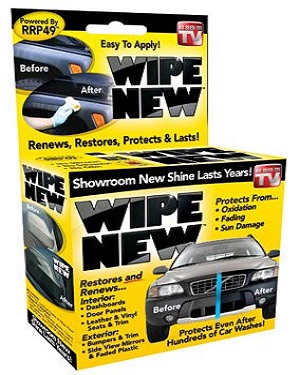

These black trim pieces start to turn white and chalky within a few years. The good news is this allowed chemical companies to start producing products meant to restore these failing trim pieces. With that said, even garage kept automobiles with plastic trim aren’t much to look at 25 years down the road. Another place that chrome once dominated was the grill and trim around the headlights.

Beautifully styled chrome grills with chrome headlight bezels and thick glass sealed beam headlights really made you feel like you got your money’s worth when purchasing the automobile for $3500. Now we spend $50,000 on an automobile with plastic grills and clear plastic lenses over the headlights. Within five years the clear lenses start to turn milky and reduced visibility supplied by the headlights. Once again companies stepped in to make a chemical repair kit that repairs the damage for a short period of time.

We can’t talk about plastic automotive technology without discussing the area of the automobile where it all started. The interior trim and door handles. Automotive reviewer’s use to complain about cheap feeling interior parts and subtracted points from the vehicle’s overall score. Now they don’t even bother complaining about the issue, because there’s no automobile that doesn’t suffer from an overabundance of plastic parts. However, when you get out of a Toyota Corolla and the door release breaks off in your hand you begin to understand the plastic automotive technology problem.

Plastic Automotive Technology in the Engine Compartment

Let’s sort out some facts before we start talking about the problems with plastic automotive technology in the engine compartment. Automotive designers started working on plastic engines in the 1970s. Ford built a version based on the 2.3-liter Pinto engine and it weighed 152 pounds. With that said, it required stainless steel cylinder sleeves. Nevertheless, it sheds nearly 400 pounds off of the four-cylinder engine’s total weight.

The question is the longevity and the reliability of plastic engine components. When discussing plastic engine parts with my engineer friends, they don’t understand my concern. However, as a mechanic with his hands in the engine compartment I’ve seen the problems first hand. More specifically, cracked plastic parts that would not have failed if they made the component from a metal alloy.

Let me give you an example of plastic part failure on the Ford 4.6 L engine. We find this popular motor in the Ford Mustang, F150, Crown Victoria and Explorer sport-utility vehicles. The 1997-2001 Ford V8 rolled off of the assembly line with a 100 percent plastic intake manifold. Within a few years, this engine became known for overheating with normal usage. The motor developed a coolant leak from the front of the plastic manifold. This triggered the check engine light and low engine coolant warning light.

The engine coolant leak stemmed from a factory defect which caused cracking of the front coolant passages. The common leak leads to engine overheating issues. Between 1999 and 2001, Ford released an updated version of this plastic intake manifold, known as the ‘PI’ version with a metal coolant passage on the front of the intake manifold, to prevent repeat failure. Ford eventually settled the class-action lawsuit and reimbursed owners $735 per incident. General Motors didn’t learn from Ford’s mistake as they also built defective plastic intake manifolds on the 3800 series V-6 engines.

Final Thoughts about Plastic Automotive Technology

I changed the oil on a 2014 Chevrolet 1.8 L four-cylinder engine twice a year. This last time, while under the vehicle, drops of coolant pelted my face. After enduring this form of Chinese water torture and completing the oil change I investigated the leak. I found a cracked plastic thermostat housing on this Chevy Cruze. To me this just indicates another plastic engine part that’s not going to stand the test of time.

The weight reduction benefits solidify the need for improving and deploying plastic automotive technology. The other advantage of plastic materials becomes the cost reduction factor. However, I don’t see the prices of automobiles, with more plastic parts, making the car more affordable for consumers. In fact, it’s just the opposite. What I see in many circumstances becomes the increased cost of ownership, because of the need to replace failed plastic components.