How to deal with Stripped Oil Drain Plugs

After performing well over 2000 oil changes I think I have seen it all as far as things that can go wrong with this simple service. The focus of this article will be on oil drain plugs and how to solve some of the most common problems associated with them during oil changes.

At the very bottom I will include some of the tools and replacement parts that are mentioned. I have seen damaged oil drain plugs ever since I first got into the auto repair business in 1984. Although it was far less common in the old days due to better materials. Back then most of the damage would be taken by the softer drain plug instead of damage occurring to the threaded hole inside the heavy steel pan.

Even if there was damage to the threads in a metal oil pan you could usually chase them with the proper sized tap. But as time went on we started to see the quality of the steel oil pan start to tumble as auto companies used cheaper and thinner parts to save money and reduce weight. Then they took this a step further and started using stamped aluminum oil pans. This meant a whole new series of problems associated with a stripped oil drain plug. Now it’s just as common to see a severely damaged hole in the oil pan as it is to come across damaged threads on the plug itself.

Simple Preventative Solutions for Oil Changes

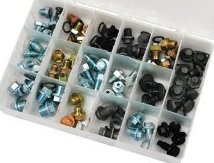

Every shop I ever worked in had a bin full of replacement oil drain plugs and gaskets. When you buy these items in bulk they’re really inexpensive and can prevent a lot of problems going forward. Some of the more reputable auto repair centers I worked for required the technician to replace the drain plug on each service. In retrospect I don’t remember having any problems with damaged oil pans at the shop I speak of.

Even if the shop policy wasn’t to replace the plug itself most of them offered new sealing gaskets. This was a good business decision and reduced comebacks. In some cases threads are not provided all the way up the shaft of the drain bolt. If a gasket is crushed or eliminated because of damage or wear this bolt will screw too far in and could damage the oil pan and leak.

Tools that Solve Problems with Oil Drain Plugs

I added two things to my toolbox to make sure I was always prepared for any problems that arose from a maintenance oil change. The first one is an oil pan repair kit. This kit comes with inserts. Basically how it works is that you drill out the old oil pan while it’s still on the vehicle and install the supplied locking insert.

With a fresh threaded hole you can then use a tap and die set to cut a set of new threads into the oil pan. I have done this repair several times and never had any problems. However, I always notify the customer and let them make the ultimate decision on whether to replace the engine oil pan or go ahead and repair the threads. Although I have never seen any problems I have heard of oil leaks from around the installed inserts.

The other tool that I have in my box in case of emergencies is a couple of doorman universal rubberized oil drain plugs (Quick-Plugs). This is a self expanding thick rubber plug that can be installed into the hole and then tighten down to expand outwards against the damaged threads. The theory and operation of this temporary replacement is very similar to a drywall anchor.

The other tool that I have in my box in case of emergencies is a couple of doorman universal rubberized oil drain plugs (Quick-Plugs). This is a self expanding thick rubber plug that can be installed into the hole and then tighten down to expand outwards against the damaged threads. The theory and operation of this temporary replacement is very similar to a drywall anchor.

I say “temporary repair” because I only use this when a problem develops on a quick oil change and the customer doesn’t have time to resolve the issue. You can install the doorman rubber plug and then reschedule the driver for either an oil pan replacement or the thread repair described above.

Quick Oil Change Alternatives

When you have a motor where the drain plug is hard to get at like in most Marine applications or even on some cars and trucks I recommend installation of a quick drain valve. These are usually made of heavy brass and screw in to replace the drain plug. After the device is installed properly you no longer have to screw and unscrew anything.

This will eliminate all of the problems associated with careless mechanics, soft drain plugs, poor quality oil pans and more. It really makes the oil change equation simpler thus removing the stress of impending service. Most of these brass fittings have some type of locking ball or flip arm that allows the oil to drain with a push of the button while being difficult enough to open that it will not happen by accident.

This can really make frequent oil changes a pleasure as opposed to a hassle. Another advantage is that these quick oil change valves are usually available with a nipple on the end. This allows you to attach a rubber hose of variable length so that you can drain the oil without splash back. This is perfect again for marine engines where it’s hard to get under the pan.

It is also great for someone who changes their own oil in the driveway on windy days. This allows you to lay the rubber hose into the drain pan. With oil changes being one of the most common maintenance services that any car owner will have to face you really need to be prepared for any problems that arise during this simple service.

The worst-case scenario is replacing the engine oil pan. These parts can be expensive depending on the model of vehicle. Labor can also be expensive depending on the year, make and model. Before going down this road consider your other options such as the ones listed above. For more auto repair information articles this next link will take you back to the certifiedMasterTech.com blog.